- All the parts and assemblies coming in contact with the powder are made of RTDPF-60 and easily removable for mandatory autoclaving / sterilization.

- Multiple dosing of dry syrup powder or change over of container size and different fill size is possible by just changing the bottle separator or the size of the position respectively.

- Total filling unit and conveyor speed is synchronized and eliminates the separate setting of each unit.

- Slat conveyor belt to prevent jamming of assembly due to spillage of powder.

- Special clutch system is provided in the bottle separator for safety purposes.

- No bottle, No-Fill’ system eliminates waste of costly powders

- High Volumetric filling accuracy of + 2% of uniform density of dry Syrup Powders can be ensured by setting the depth of piston in the PORT of the POWDER WHEEL

- The motor is provided with appropriate Contactors and Relays for the protection against any overload or jamming

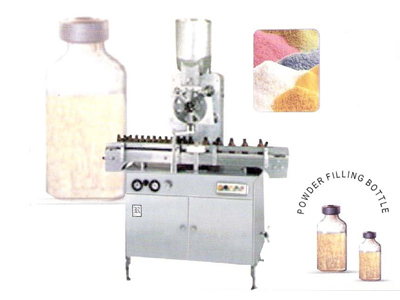

Fully Automatic Powder Filling Machine

Fully Automatic Powder Filling Machine